When beginning any project it’s important to know how it will be published – but never more importantly than when considering Print. Although some projects once designed can be easily converted to multiple formats, some cannot, i.e. black and white to color, so it’s essential to know what the end product will be.

Today the internet has made print media virtually obsolete which for both large and small businesses is a good thing when you consider the cost of involved in printing collateral materials. The cost of printing varies greatly based on multiple factors such as number of colors, type of colors, paper options, type of press used and any number of additional coatings, cuts, dies and bindings. And then of course, quantities.

A good starting point would be to discuss a budget and quantities required with your client.

When printing, the first cost to consider is color. When using a traditional press, plates are created for each color used in a piece, and the piece is in turn fed through the press once per color. Thus increasing cost per plate and rounds fed.

Black and white or grayscale printing: by far the most cost effective print option. In black and white printing all text and artwork is created using only the [Black] color swatch and any tints or shades (percentages) of the same. When using design software it is imperative to specify the Black swatch, not the Registration swatch which looks like black or any number of other Pantone Matching System (PMS) options or these can result in additional cost and undesirable print results. In addition, any images utilized must also be in black and white or grayscale mode. Although considered boring and ugly by some, many beautiful pieces can be created using only black.

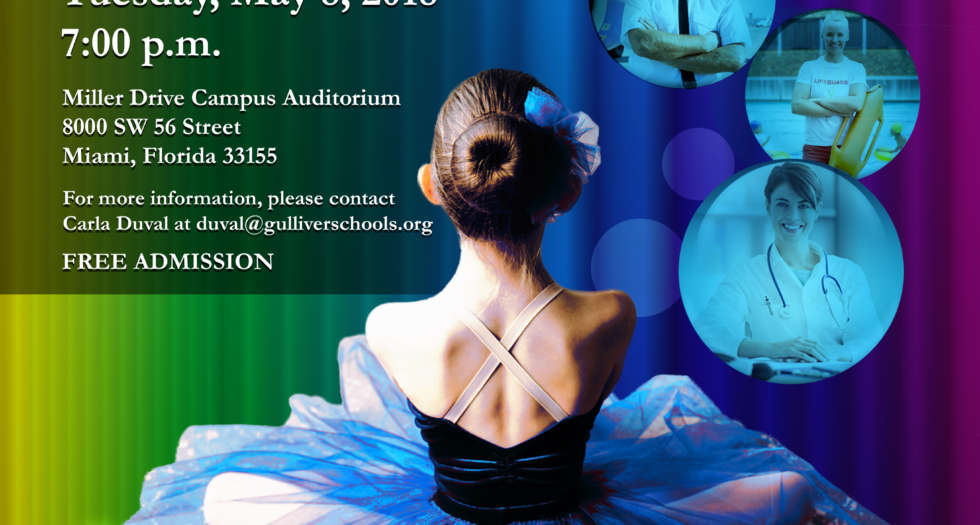

CMYK or full color/four color process: CMYK meaning Cyan, Magenta, Yellow and Black (also designated as K) are the basic colors used to create four color (or full color, “photograph like”) process printing. When designing a full color piece any variation of colors can be used as long as they are produced using combinations of the CMYK formula. This includes tints and shades of each color created also. Any images used in this piece must be in CMYK mode. Some design apps allow you to use RGB images as well and automatically convert the images to CMYK when exporting your final print file.

PMS colors: Pantone Matching System, more commonly referred to as, PMS colors require a separate plate and feed through the press for each. The interesting thing is that they can be used in addition to or instead of any of the above processes. For example, maybe you want something different than a simple black and white piece without the cost of a four color process- replace your [Black] swatch with a PMS designation and viola! you have a totally different look for a fraction of the cost of a 4 color process.

When using color in printing, digital printers have revolutionized the industry and cut the cost of production by half. Digital printers don’t use plates, don’t require setup nor proofing. The downside is the quality is greatly reduced. Still, some very effective pieces can be produced on a digital printer. One item of importance to note when using a digital printer is if your digital printer uses CMYK or RGB inks.

RGB printing: Red, Green and Blue are the default color modes used by scanners, digital cameras and your computer monitor. Although digital printers are available in CMYK some quick print shops use RGB printers instead. The greatest difference being the absence of black. Ask your printer before sending your file which he plans to use and prepare accordingly. You will be much happier with your final result.